From AI vision collaborations to MOSFETs and TVS diodes, innovations in the automotive electronics space continue to race ahead.

There’s a lot happening these days in the world of automotive electronics. This roundup of transportation semiconductor news hits driver assistance with a new AI-assisted electronic mirror (e-mirror), electric vehicle (EV) charging with a new high voltage MOSFET, and EV battery management with an automotive grade AEC-Q101 low-clamping voltage TVS diode.

AI-Powered Mirror Replacements

A new vision system for advanced driver assistance systems (ADAS) in large trucks comes out of a partnership between Gauzy and Ambarella. Gauzy has a wide variety of lighting and vision systems and Ambarella produces the CVflow AI system on chip (SoC). The two companies partnered to create an AI-powered smart vision camera monitor system (CMS).

Ambarella AI SoC and Gauzy Visions Systems replace optical mirrors with AI-driven smart displays in commercial vehicles.

The CMS is targeted at replacing side and rear-view mirrors in commercial vehicles with e-mirrors. The existing mirror structure is replaced with an external camera and a display in the truck cab. Being camera based, mounting flexibility is greatly enhanced and the truck receives a small fuel economy benefit from the reduced drag of the much smaller camera.

Unlike conventional optical reflective mirrors, the Smart-Vision CMS delivers safety-oriented augmented reality. It adds real-time road hazard recognition and maneuvering lines for trailer calibration and uses AI for interpretation.

With night vision and IR sensitive cameras, the e-mirror is capable of displaying clear lines of sight and objects in a variety of weather and lighting conditions. The Ambarella CVflow AI accelerator is capable of self-learning and predictive AI when combined with the Gauzy camera/display system.

The system is already operating in a number of commercial Ford trucks. It can be designed as new equipment or retrofitted to existing fleet vehicles.

New MOSFETs from Infineon Target EV Charging

Meanwhile, Infineon has introduced a new 1200 V MOSFET for automotive Tier1 chargers and OEM On-board Chargers and DC-DC converters in electric vehicles. Along with the product announcement, Infineon also announced a design win with the MOSFET slated for use in FORVIA HELLA’s chargers . FORVIA HELLA, of Munich Germany, selected the AIMCQ120RxxxM1T for its next generation 800 V DC-DC charging solution.

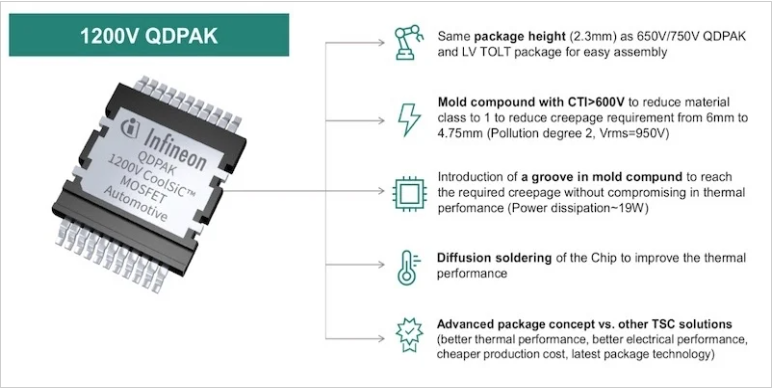

infineon’s 1200 Volt EV charging MOSFET.

The QDPAK MOSFET is designed for superior thermal performance with a reduced need for back-side PCB cooling. The 1200 V QDPAK has the same height (2.3 mm) as their lower (650 V /750 V) voltage parts for easier and more consistent PCB assembly process. The MOSFET utilizes Infineon Gen1p silicon carbide (SiC) technology to deliver lower switching losses and solid performance.

It has a zero-volt turn-off which can reduce circuit complexity and parts count when compared to conventional MOSFETs with negative gate voltage turn-off requirements. Gate voltage in the new parts (V GS ) ranges from 20 V to 0 V. Reducing the parts count and simplifying the cooling allows for more compact on-board chargers and DC-DC converters.

The AIMCQ120RxxxM1T parts come in current ranges from 116 A to 18.6 A, with corresponding R DS values from 19 mΩ to 160 mΩ.

Littelfuse TVS Diodes Help to Improve EV Battery Management

For its part, Littelfuse has added to its automotive semiconductor portfolio with an ultra-low clamping voltage TVS diode. The component is designed for battery management systems (BMS) in 14 to 20 cell, 800 V EV battery electric vehicles. BMS are critical for both safety and battery pack longevity in EVs and clamping diodes are a key component in the systems. The ultra-low clamping voltage (Vcl) allows for better limiting of transients which leads to better protection for the battery management integrated circuits (BMIC) and analog front-end ICs (AFE).

Littelfuse TPSMB-L series are low clamping voltage TVS diodes.

The electrical environment of an on-the-road EV battery pack is a harsh world of noise, spikes, transients, and thermal variations. Yet sensitive precision electronics must be able to survive for the decade or more life of the power pack. Key to that survival is a fast responding precision TVS diode.

The new Littelfuse surface mount TVS diodes have 600 W PPPM (peak pulse power) capability at 10/1000 μs waveform, with a repetition rate (duty cycles) of 0.01 %. Their response time is typically less than 1.0 ns from 0 V to VBR min. The three diodes in the line have maximum clamping voltages at Ipp of 96.0 V, 100.0 V and 114.0 V.

The high speed, small surface mount package and standards compliance make the TVS diodes ideal for protecting I/O interfaces, VCC buses, and other vulnerable electronics used in automotive applications.